Roselick Consulting (Pty)Ltd

Contact: Jon Kerr (Managing Director)

Phone: +27 (82) 372 9284

Email: jon.kerr@roselick.co.za

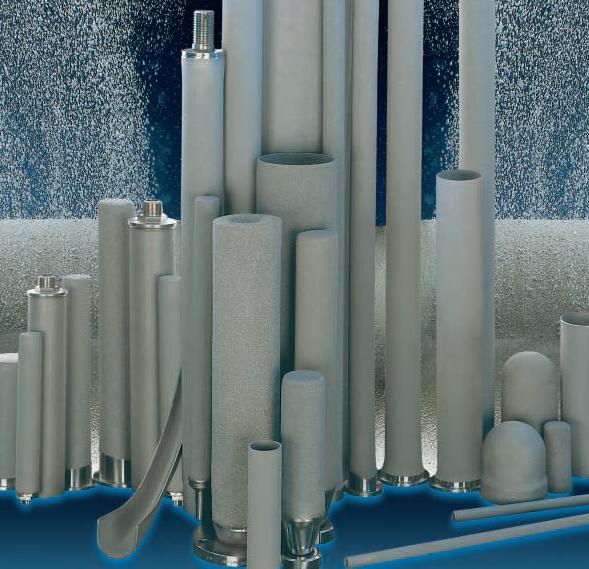

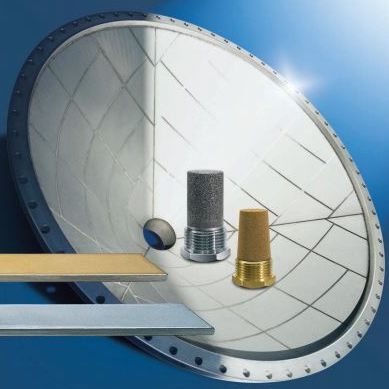

Consultants and importers in Sub-Saharan Africa for GKN Sinter Metals products

Terms & Conditions of Sale